Blog

From Rust to Riches: Inside a Frame-Off Defender Restoration

Custom Land Rover Defender Interiors: Crafting a “Private Jet” Cabin on Wheels

August 6, 2025

The Restomod Revival: Why Classic Mustangs Are Roaring Back

August 20, 2025Restoring a classic Land Rover Defender to better-than-new condition is a meticulous art. In a frame-off rebuild, the truck is stripped to its bare chassis for a complete transformation. Experienced ECD restorers tag and bag every part during disassembly, inspecting the frame and components piece by piece. The result is a Defender reborn.

A Defender 110 covered in rust and wear can end up looking and performing like a modern luxury machine.

Every stage of the restoration - from chassis prep to paint and testing - follows best practices so that the final vehicle feels new again.

We'll step through the process, highlighting galvanizing the chassis, modernizing the electronics, sourcing quality parts, and the white-glove care clients expect.

Steps To Taking A Derelict Land Rover Defender 110 From Old To New

The first step is total disassembly

Each Defender is stripped to its bare frame, and every part is meticulously inspected. Technicians catalog reusable components and mark worn sections for replacement.

Stripping Down and Initial Inspection

Complete Disassembly

The Defender is torn down completely. Body panels, doors, engine, transmission, axles, and wiring are all removed so the chassis is fully exposed. Usable parts (nuts, bolts, sturdy body panels) are tagged and boxed for reuse; anything rusty or outdated is set aside.

Part-by-Part Inspection

Craftsmen inspect every piece. The chassis is examined for weak spots, and old components (bearings, bushings, hoses, etc.) are tested. This lets the builder decide what to refurbish vs. replace.

Rust Assessment

With the frame bare, all corrosion is identified. Rotten steel is marked for cutting out and replacement. Body rust is eliminated and the frame is "reinforced to ensure structural integrity" for modern use.

Each of these steps ensures the rebuild starts on a rock-solid foundation. Any historic patina is stripped away so that the restoration can truly begin.

Chassis and Body Restoration

Sandblasting and Repair

The frame and body panels are sandblasted or chemically stripped to bare metal. Any rusted sections of the frame are cut out, and new steel is welded in. Shops reinforce the rails and cross-members to handle added performance. ECD emphasizes that before adding luxury or power, the frame must be fully reinforced and protected, and all rust removed.

Galvanized Chassis

For ultimate rust prevention, many builders use a hot-dip galvanized Land Rover chassis. The bare frame is dipped in molten zinc (then usually painted or e-coated), creating a corrosion-proof coating. This process basically makes the steel impervious to rot.

New Hardware

All chassis fasteners and components are replaced with modern equivalents. Builders fit new spring hangers, shackle plates, and frame brackets where needed. Every bolt and nut is upgraded to zinc-plated or stainless steel grades. Typically, A4-80 grade (stainless) bolts on suspension mounts and even galvanizes hubs, flanges, and steering parts to prevent future rust. This attention to hardware means the restored Defender won't deteriorate as the old one did.

This thorough chassis work leaves a Defender frame that is stronger and more durable than stock. Once the frame is straight, solid, and sealed against rust, the team can move on to rebuilding all the vehicle systems.

Powertrain, Suspension & Brakes

Engine Rebuild or Swap

With the chassis ready, a new (or freshly rebuilt) engine goes in. Clients often upgrade to more powerful or efficient motors: options include rejuvenated original turbodiesels, GM LS-series V8s, Cummins diesels, and even electric powertrains. The transmission and transfer case are overhauled in tandem. ECD’s Defender program offers multiple drivetrain solutions - from modern V8s to all-electric conversions - all mated to upgraded transmissions. Radiators, coolant hoses, and fuel systems are also replaced or uprated to suit the new engine.

Suspension Upgrades

All suspension components are new. Typically, the build includes brand-new springs, shackles, and updated shock absorbers (often nitrogen-charged units for a smooth ride). ECD and others fit purpose-designed progressive springs and shocks tailored to the vehicle's use. Bushings, radius arms, and steering knuckles are all replaced or refurbished with strengthened parts.

Brakes

The brake system is modernized for safety. Almost every frame-off Defender gets disc brakes on all four wheels (vented rotors up front) to replace the old drums. New calipers are installed and typically zinc-coated; stainless steel lines are fitted for durability. In short, stopping power is vastly improved over stock.

After these mechanical upgrades, the Defender's chassis and running gear provide a much more refined driving experience - handling and stopping better than a 1980s truck ever could. Technicians install and tune the restored engine and drivetrain. In a frame-off rebuild, the engine may be overhauled or upgraded - for example, a GM LS-series V8 or modern turbo-diesel - with all new transmission, cooling, and exhaust components. Suspension (progressive springs, shocks) and four-wheel disc brakes (vented front rotors with stainless lines) are also fitted to modernize handling.

Electrical Overhaul & Modern Tech

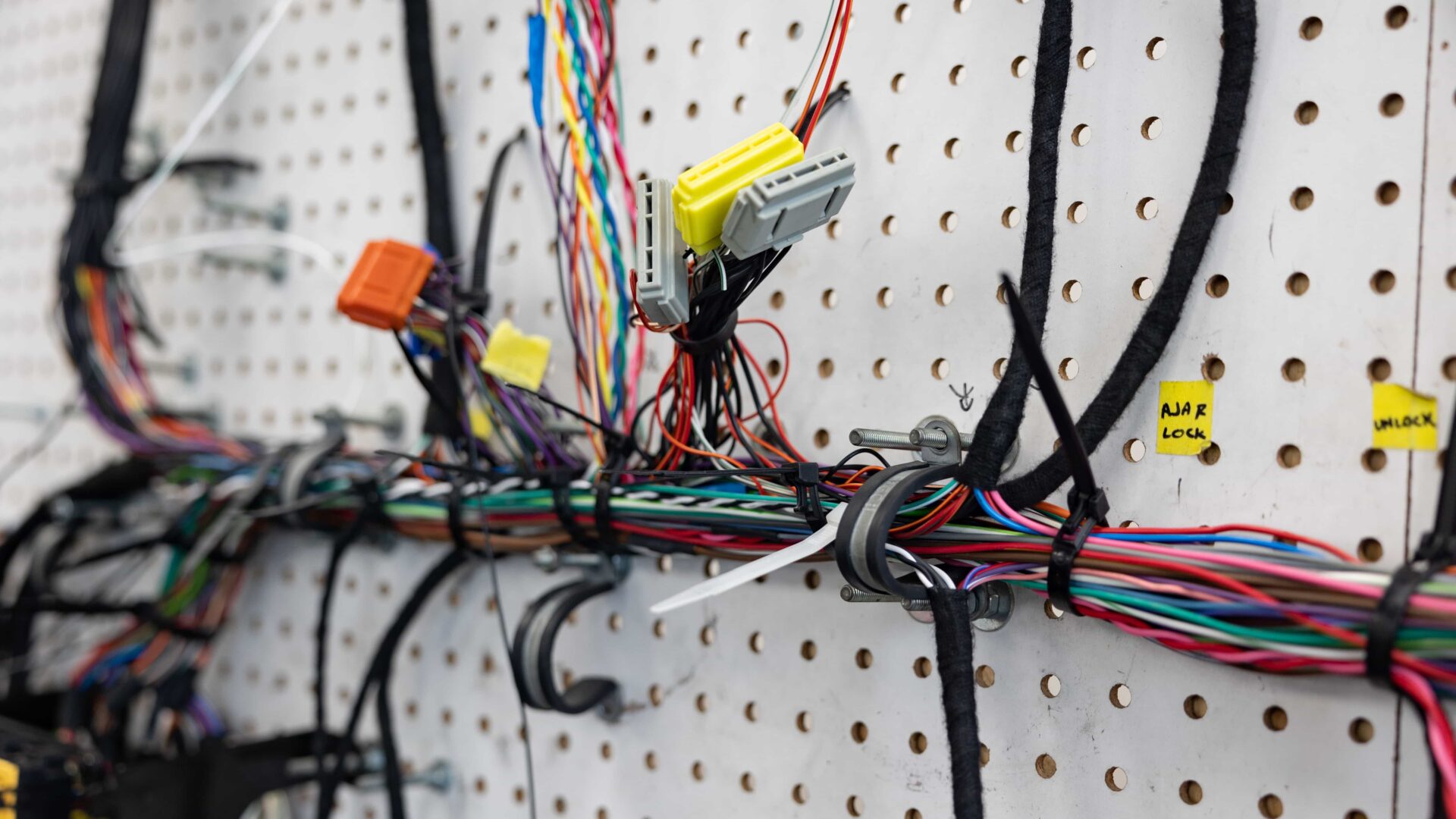

Complete Rewiring

The Defender's old wiring loom is entirely removed and replaced. A brand-new harness is installed to power everything from lights to gadgets. The new wiring is indispensable for a restored Defender; fresh cables are run for all electrical components, and every custom build receives a complete electrical overhaul to support upgrades.

Lighting & Accessories

Modern LED headlights and auxiliary lights are usually fitted for safety. The new wiring supports powerful off-road lamps, winches, and any added accessories (i.e. charging ports, roof-rear cameras, etc.). By renewing the electrical foundation, builders ensure reliability when running radios, heated seats, navigation units, and other add-ons.

Upgraded Dash & Controls

Old analog dashboards are often replaced or retrofitted. Some restorations include custom digital dash clusters or tablets behind classic bezels. The fuse box and relays are all new to handle higher loads. In short, the Defender gets a tech refresh inside, while maintaining the rugged look.

This wiring and electronics work makes the vehicle safe and comfortable for today's standards. Off-roading or daily driving, the owner can trust that the electrical systems (lighting, instrumentation, climate control, infotainment, etc.) are up to modern expectations.

Interior and Luxury Trims

New Upholstery

The cabin is rebuilt from the floor up. The seats, headliner, carpets and door panels are all new. Craftsmen use high-quality materials - hand-stitched leather or durable marine-grade fabrics - to give a premium feel. Everything is tailored to the client's taste (colors, textures, stitching).

Trim & Comfort

Dashboards are refurbished or replaced with custom pieces. New HVAC controls and vents are added so the Defender can have efficient heating and air-conditioning. Modern sound-deadening material is installed under the carpet and panels. Premium audio systems and digital screens (for stereo, navigation, backup camera) can be integrated seamlessly. Small details like a wood-rim steering wheel, custom gauge faces, or a suede headliner can be added for that luxury touch.

Finishing Touches

All hardware in the cabin (handles, knobs, pedals) is refreshed. For example, ECD notes its builds have "handcrafted interiors" with bespoke trim and digital displays to marry classic design with modern comfort. Custom roof racks or roll cages might be installed if desired. Essentially, the customer steps into a vehicle that feels brand-new inside, but still looks unmistakably Defender.

The attention in this step ensures the drive is comfortable and stylish. Clients often describe the result as a personalized luxury SUV wrapped in timeless, rugged charm.

Paint, Assembly and Finishing

Body Prep and Paint: With systems rebuilt, the body is prepped for final finish. Panels are straightened or replaced for the perfect fit. A high-end primer and paint system is applied in a dust-free booth. Owners choose the color: some stick with an original Defender shade, while others pick a custom hue. Whatever the choice, shops use premium automotive paints for a flawless finish.

Reassembly

The vehicle is put back together in the reverse order of the teardown. Every part is reinstalled with new seals, gaskets, and fasteners. All weather seals, glass, and exterior trim are replaced so panels align perfectly against the elements.

The grille, badges, lights, bumpers, and mirrors are all fitted with care. This is where meticulous craftsmanship shows: tight panel gaps, clean wiring routes, and no leftover scratches.

Final Calibration

Once assembled, the shop performs all alignments and system checks. Lights are aimed, tire pressures set, and engine synced. The Defender is inspected for leaks, noises, or defects one last time before handover.

By the time the Defender rolls out of the shop, it has brand-new paint and internals. Every stitch, bolt, and wire has been refreshed or upgraded. The process truly yields a flawless finish worthy of a showroom.

Quality Control and Delivery

Road Testing

Before delivery, each Defender is road-tested. Builders verify that brakes, steering, and suspension feel correct. Any minor adjustments (throttle calibration, brake balancing, alignment tweaks) are made until the truck meets spec.

Documentation

Every owner gets a complete build dossier. Owners get receipts, before/after photos, and details of each upgrade. Plus, they can follow along in real time online as their Defender goes through its metamorphosis. This transparency builds trust, especially since ECD uses only the best parts for durability.

Client Care

Given the six-figure budgets, white-glove service is expected. ECD customers work with a single project manager who provides regular updates, schedules viewings of the vehicle at milestones, and handles logistics (compliance, shipping).

The final QA and client experience are as polished as the build itself. The Defender that comes out is not only cosmetically impeccable but is ready for real-world use and adventure. It blends classic character with modern safety and performance - truly a "one-of-one" vehicle for every client.

Ready to begin your build?

Start designing yours today.

TOP RELATED STORIES

FREQUENTLY ASKED

QUESTIONS

No FAQs configured yet.